Click to Call

Click to Call

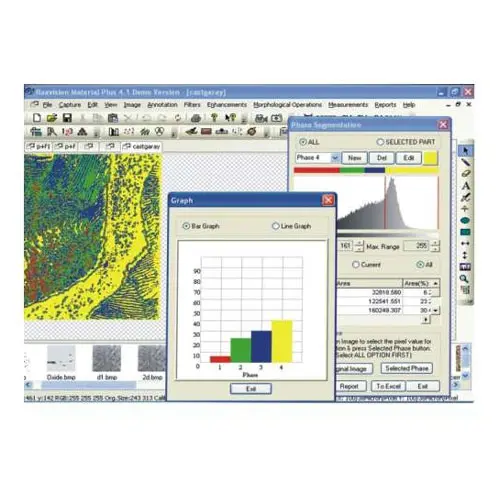

Metkorp Equipments Pvt. Ltd is a Leading CAST Analysis Software service company in Nagpur. We offering CAST Analysis Software at Best Price in Nagpur. The offered CAST Analysis Software in Nagpur is valued by our patrons for their quality. The complete range of CAST Analysis Software is having export quality supplying in Nagpur. The offered CAST Analysis Software in Nagpur, is checked on various parameters by our quality controllers.

CAST Analysis Software Services, Supplier in Nagpur, CAST Analysis Software in Nagpur, CAST Analysis Software at best price in Nagpuri

FEATURES

| Praised For | :- | • Ease of operation • User friendly module • Swift working • Simplifying complex tasks |

| Demanded For | :- | • Steel plants • Oil & Gas Industry • Metal forging Industry • Material Science |

Software analysis and measurement with CAST Software Suppliers. Software analysis and measurement with CAST Software. The Material Analysis Software that we deal in is used in varied applications and brings huge appreciation for the company as well. The Material Analysis Software that we bring forth is properly tested before its delivery to the esteemed clients in the global market.

SPECIFICATION

IMAGE EDITING

• Cut, Copy, and Paste.

• Selected copy by free hand AOL controlled by four arrow keys available on keyboard or mouse with zoom preview.

• Crop, duplicate, restore

• Resize

• Compression

• Conversion to other format BMP, JPG, TIF, PNG, GIF & PSD

• Flood fill or spray with selected color at selected portion.

• Grid creation; 5X5, 10X10 & 100X100 grids (or cells).

• Drawing tool curve, line, square, and circle with node control and provision to change color & thickness of the line.

• Write text in any color or font.

• Pointer to place on an object in either of four directions with provision to change its color & thickness.

• Eraser works only on line, arrow or on any drawing tool.(not on original image)

• Camera Lucida

• Montage feature to merge stored image together. Useful to Merge different focuses of same image.

• Image stitching.

• Highlighter.

• Pixel by Pixel Correction by key board.

• Multiple image folder with Search facility.

• Filter application on selected area.

VIEW

• Zoom in/out

• Zoomed preview

• Rotation at 90, 180,270 or custom

• Image flipping; horizontal or vertical axis

• Intensity histogram.

• Image Information

• Redo/Undo on all operations.

IMAGE PROCESSING

• Background subtraction and contrast enhancement of color or grayscale images

• Arithmatic image functions (Boolean Math; Add, AND, OR, XOR, DIFF, MIN, MAX, +, -, /, *, And Simple).

ROUTINE FILTERS

• Invert, Brightness, Contrast, Hue, Saturation, Blur, Noise Remove, Emboss, Engrave, Gamma R, Gamma G, Gamma B, Yellow, Magenta, Cyan, Mosaic, Smooth, Desaturation, Pseudo Color, Colorize, Oilify, Despeckle, Posterize.

SPECIAL FILTERS & KARNELS

• High Boost, High Spatial, Low Pass Spatial, Ranking (Max, Med, Min), Point detection, Line detection, Homogeneity

EDGE DETECTION

• Laplacing, Sobel, Krisch, Prewitt Gradient, Shift & Difference, Combine, Contrast Base, Quick, Range And Variance.

MORPHOMETERY

• Skeletonizing, Pruning, SKIZ, Histogram Equalization, Histogram Smoothing, Histogram Peak, Histogram Valley, Segmentation by Over/Under and Quantized, Contoring, Dilation / Erosion on Binary, Gray & colored Images, Opening/ Closing on Gray & Binary Images, Special Opening/Closing, Split/Combine of RGB, YUV, YIQ, XYZ, & HSL, Changing any Image to 1, 4, 8 & 24 bits, Medial Axis. Transformation, Halftone.

Image Addition, Image Average, Image Subtraction, Image Multiplication.

MEASUREMENT

• Spatial calibration

• Line measurements for Distance, Length, Width, Perimeter, Angle, Three Point Radius.

• Area by enclosed line controlled by four arrow keys available on keyboard arrows with zoomed preview.

LIVE MEASUREMENT

• Live Measurement can handle monochrome (8 bits) and color (24 bits) images. Multiple images of any size can be opened and displayed on the screen for analysis or comparison. The software support most common formats BMP, JPEG, TIFF, PNG, GIF & PSD. The live image can be observed and captured on the same platform. And the software also support Measurement On Live Images. Live measurements for Line , Ellipse , Rectangle , Circle , Center Circle , 3 Point Circle , 2 Line Angle , 3 Point Angle, Center to Center, Parallel line Perpendicular line , Point to Point Horizontally, Point to Point Vertically , Poly line ,Perimeter , Curved Area , Curved Length , Perpendicular Distance, Min Distance, Max Distance, Circle to Point and Chord.

COUNT AND CLASSIFICATION

• Identification of objects in an image, count them, obtain several features measurements. Objects identification by user or automatically. User defined classification on basis of size or intensity.

THRESHOLD PARTICLE MEASUREMENT

• Manual, Auto bright and Auto dark methods to identify intensity range defined object to be measured. Various calculation & measurements available for selected Particle are; Dimensions, Area, Perimeter, Feret Length, Min/Max Radius, Thread Length, Thread Width, Fibre Length, Fibre Width.

MORPHOMETERY

• Roundness, Shape, Orientation, Elongation, Equal Circular Diameter, Equal Sphere Volume.

LOCATIONAL

• Centroid X, Centroid Y, Major X1, Major Y1, Minor X1, Minor Y1, Major X2, Major Y, Major X2, Minor Y2, Box X1, Box X2, Box Y, Box Y2 & Box Area.

PHASE

• Measure area fraction & volume fraction. Identify multiple phases within Microstructure. Also delineate phases from the histogram as per ASTM Standard E562 & E1245.

NODULES

• MEASURE Nodularity as per ASTM 247 standard. The Nodules & Flakes are separated on the basis of its shape and aspect radio.

The detail measurement of each microstructure is available for further analysis. The processed image displays non-Nodules in different color. The Nodules can be classify by its range on the basis of its size & shape.

POROSITY

• They are recognized on the basis of its intensity as per ASTM B-276 standard. The measurement of each pore is displayed. The processed image displays pores in Red color.

COATING THICKNESS

This application rapidly measures the thickness or width of a coating at multiple positions along a sample as per ASTM B487 standard. Tabulated results available for min/max and mean of width measured at various points of sample cross section.

DECARBURISATION

• Measured depth or width of decarburisation occurs as per ASTM 1077 standard.

GRAIN SIZE

• The module analyze Grain image and measure the Grain no. & Grain size using ASTM E 112 , JIS G-551, E-930, E-1181, ISO 643-03, BS 490 DIN 643-03, IS-4748-88, SIS 111101 GOST 5639-82 The options for measurement available are 1. Manual Trace, 2. Popular Comparison Method, 3. Quick single Grain measurement, 4. ALA method, 5. Interception method. Various filters to make user defined templates. Grain boundary repair mathematical function.

NON METALIC INCLUSION

• Measure inclusions and report ASTM E-45, E-1245 AND DIN-50602, JIS G-552 numbers, cumulative length, width ratio.

GRAPHITE FLAKES

• Graphite Flakes length, width, distribution and percentage as per ASTM A-247-67, ISO 9451-1, DIN EN 945-94, BIS 7754 JIS G5504, IS-7754

SG IRON ANALYSIS

• The module automatically analysed & calculate Nodulanty/Non Nodulanty percentage. Determine its class and number from 1 to 8 as per ASTM, JIS, BIS & ISO standard s, Nodules per square mm is also on Etched sample it reported. Determine percentage of pearlete, graphite, ferrite and carbide.

CAST IRON ANALYSIS

• The dedicated module determines flake size from 1 to 8 as per ASTM, JIS, and BIS & ISO standards. The type distribution percentage A, B, C, D, E is calculated interactive tools. Flakes per square mm is also calculated simultaneously.

REPORT

• Three options: Direct printout with original image processed Image & Tabular results

• Export to MS Office or Excel for further modification.

One Stop Solution for Latest Metallography Equipment which You Required for Your Laboratry.